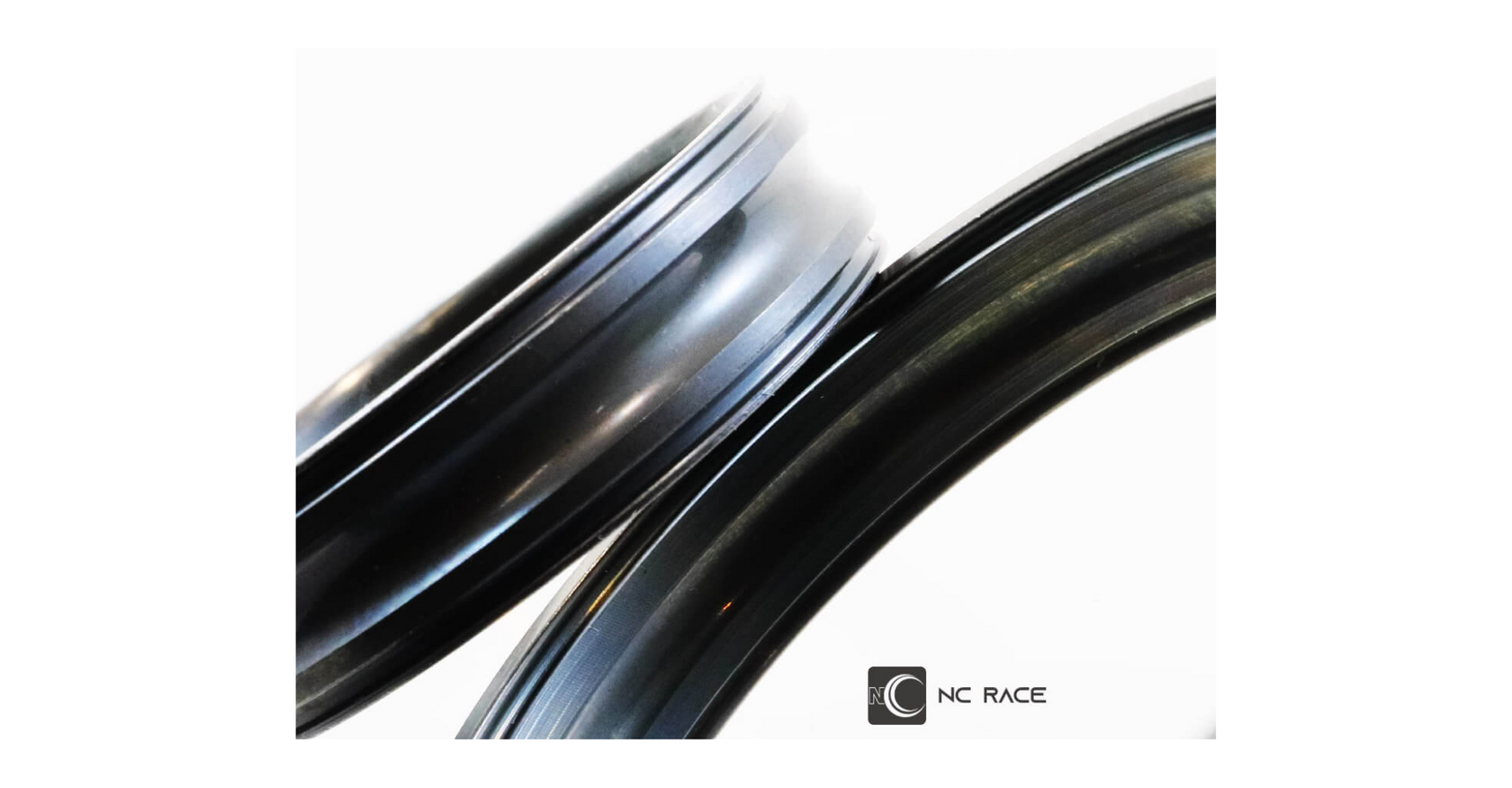

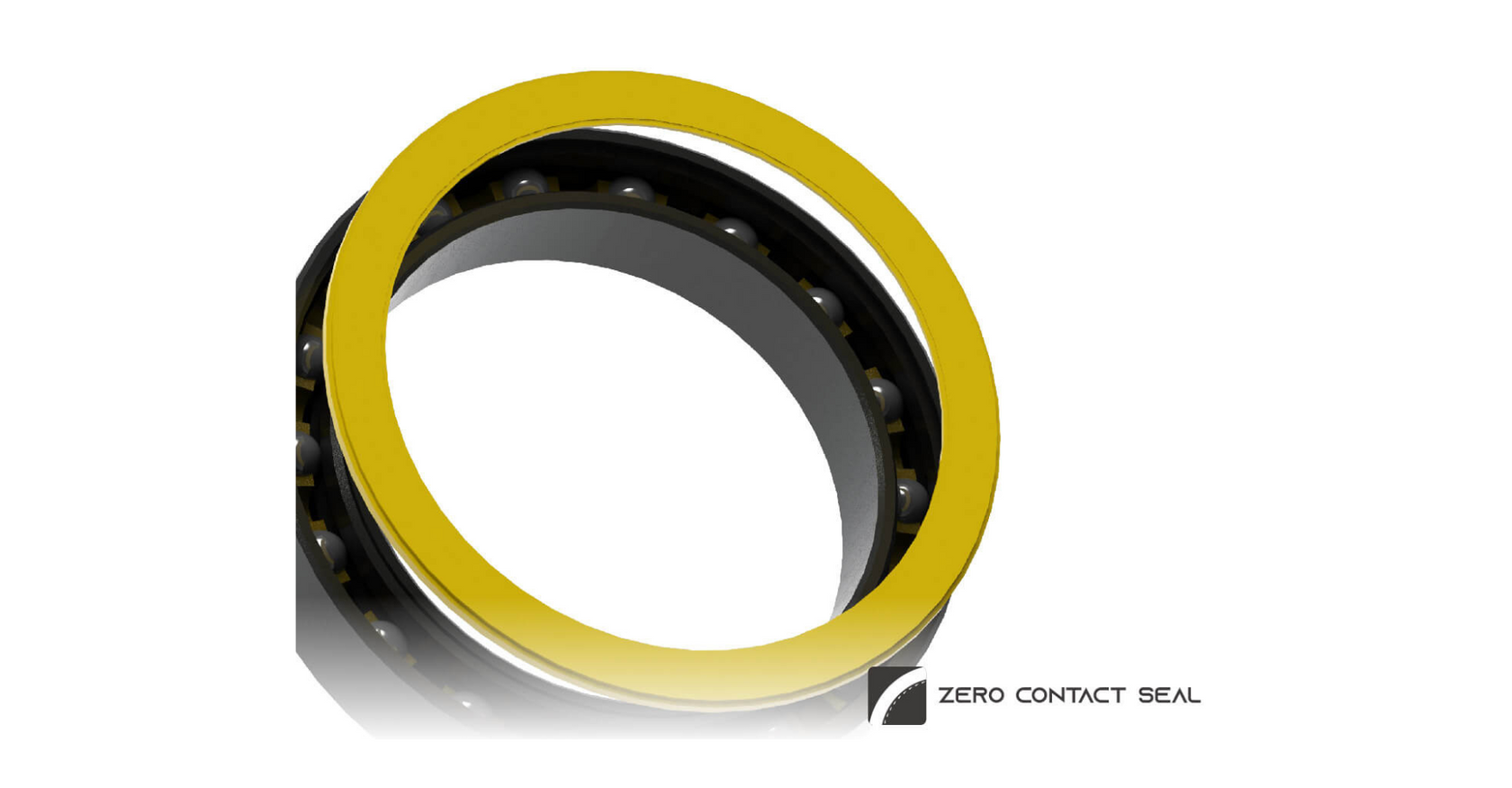

Tripeak bearings feature a metallic coating that is 75% harder than hardened steel, applied in a thin layer, also known as CERAMIC COATING, measuring 3 microns (0.003 mm) across the entire surface of the bearing races. Both the inside and outside are treated to optimize performance. This coating ensures uniform and smooth surfaces, improving corrosion resistance, even under conditions of degreaser, water or mud contamination, significantly reducing the risk of failure.

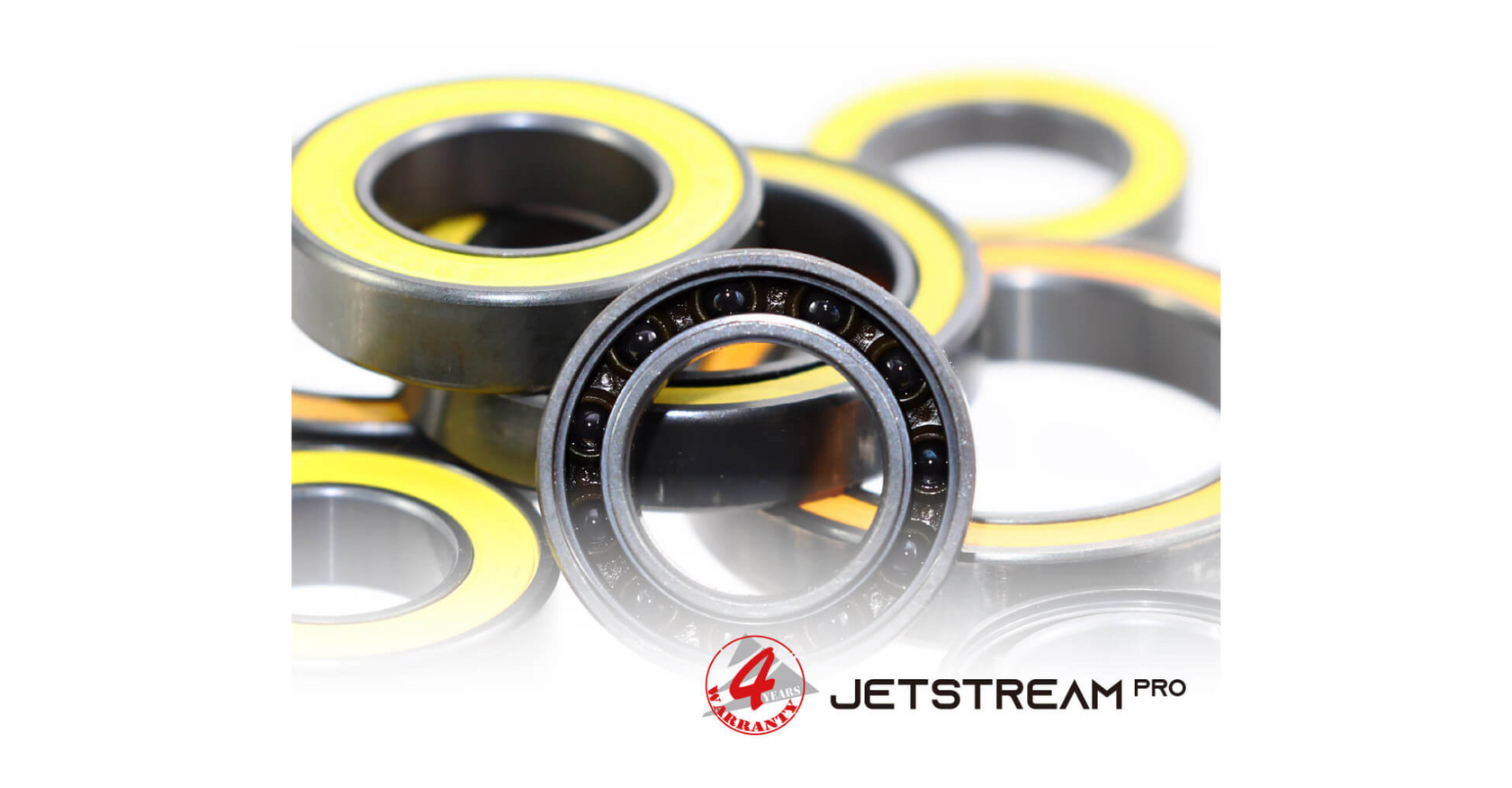

Tripeak bearings are designed to offer unmatched longevity and incredibly low friction. They are more resistant to lack of lubrication, reducing wear and damage. However, regular maintenance is still recommended.

Features:

Extremely low friction

Improved power transfer

3 to 5 times longer service life compared to industry standards